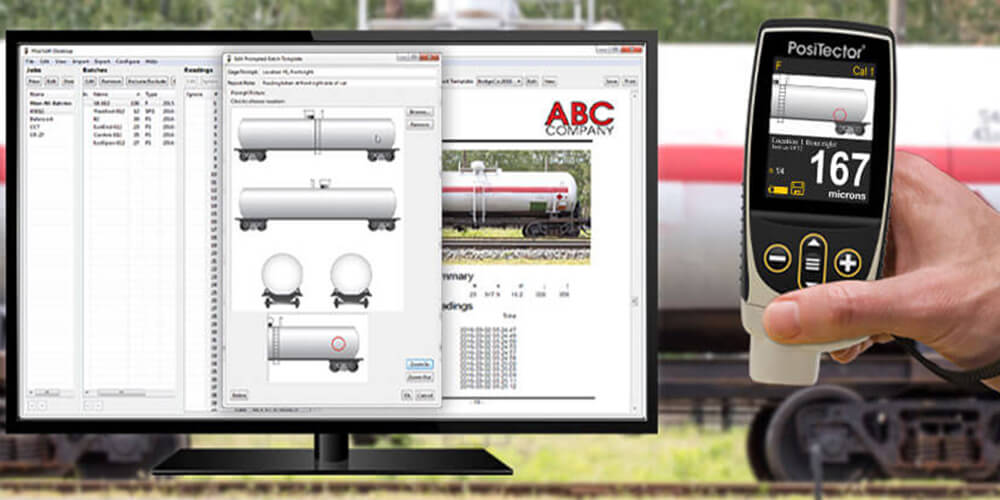

DeFelsko PosiTector 200

F.A.Q.

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the DeFelsko PosiTector 200 calibrated at the factory?

The DeFelsko PosiTector 200 arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements

The DeFelsko PosiTector 200 is factory calibrated to measure most polymer coatings out of the box without calibration or adjustment. If required, a simple gage adjustment can be made to a coating sample of known thickness as close as possible in composition to the intended application. For best results, the thickness of the sample should be equal to or slightly greater than the maximum expected thickness of the coating to be measured.

Can the DeFelsko PosiTector 200 be used to measure coatings on metal substrates?

In many cases, yes! However, the following should be noted:

- Metal Substrate Thickness: Because sound travels through metals approximately three times faster than it travels through most protective coatings, substrate thickness will largely determine the suitability of a particular coating thickness application for the DeFelsko PosiTector 200.

- Gage Adjustment: Adjustment to the DeFelsko PosiTector 200 gage’s Hi Range to eliminate unwanted metal substrate back-wall echoes is typically required for improved measurement repeatability. This process of adjustment is simplified through the use of the DeFelsko PosiTector 200 Advanced gage’s Graphics Mode. Although a DeFelsko PosiTector 200 Standard gage model has the capability to accurately measure single coat applications and a total coating system thickness of multi-layer applications, we strongly recommend the use of a DeFelsko PosiTector 200 Advanced gage model for measurement on metal substrates.

- Single Coat Applications: A minimum coating thickness of 13µm (0.5 mil) on a flat metal substrate with a minimum thickness of 1.25mm (50 mils) is usually required.

- Multi-Layer Applications –

- Total thickness: In many circumstances, the total thickness of a multi-layer coating system over metal can be reliably measured. As in single coat applications, a minimum total coating system coating thickness of 13µm (0.5 mil) on a flat metal substrate with a minimum thickness of 1.25mm (50 mils) is usually required.

- Individual layers: The DeFelsko PosiTector 200 will measure the thickness of individual layers when each layer is thicker than 125µm (5 mils) and the metal substrate is thicker than 6mm (0.25”). A greater difference in the acoustic characteristics of each layer results in a greater likelihood of accurate individual layer measurement.

A PosiTector 6000 probe is generally recommended over a DeFelsko PosiTector 200 probe for measuring coating thickness on metal substrates because –

- Lower cost

- Larger selection of probes (none requiring the use of an ultrasonic couplant gel)

- Greater accuracy

- Unlike DeFelsko PosiTector 200 probes, adjustment is not required for most protective coating properties

- Fully conform to international standards for measuring coating thickness over metal