-

Shop by Category

- Coating Inspection

- Coating Thickness Gauges

- Coatings, Miscellaneous

- DeFelsko PosiTector 200

- DeFelsko PosiTector 6000

- DeFelsko PosiTector Inspection Kits

- DeFelsko PosiTector SST

- DeFelsko PosiTest AT Adhesion Testers

- DeFelsko PosiTest DFT

- DeFelsko PosiTest PC

- DeFelsko PosiTest Pull-off Gages

- Holiday Detectors

- Oven Temperature Data Loggers

- Dial Thickness Gauges

- Dynamometers Tension Load Cells

- Force and Torque Measurement

- Cap Torque Testers

- Digital Force Gages

- Force Gauge Attachments

- Force Gauge Attachments (Imada)

- Force Gauge Attachments (Mark10)

- Force Gauge Attachments (Shimpo)

- Force Sensors

- Force Test Systems

- Mechanical Force Gauges

- Peel Testers

- Physical Therapy & Strength Test

- Test Stands, Mechanical

- Test Stands, Motorized

- Torque Calibration Equipment

- Torque Screwdrivers

- Torque Sensors

- Torque Testers

- Torque Transducers, Rotary

- Torque Wrenches

- Wire Terminal Pull Testers

- Hardness Testers and Durometers

- Horiba Water Quality Meters

- Horiba LAQUAtwin Compact Meters

- Horiba LAQUAact Portable Meters

- Horiba LAQUA Benchtop Meters

- Horiba LAQUA Conductivity Cells

- Horiba LAQUA DO Electrodes

- Horiba LAQUA Ion Electrodes

- Horiba LAQUA pH Electrodes

- Horiba Multiparameter Water Quality Meter

- Horiba Oil Content Monitor - Analyzer

- Horiba Environmental Radiation Monitor Radi

- Industrial Maintenance

- Magnetic Particle Inspection

- Moisture Meters

- Moisture Inspection Kits

- Moisture Meters by Manufacturer

- Moisture Meters for Agriculture

- Moisture Meters for Building Inspection

- Moisture Meters for Flooring & Wood Products

- Moisture Meters for Water Damage Restoration

- Moisture Meters for Leather

- Moisture Meters for Paper

- Moisture Meters for Temperature / RH

- Moisture Meters for Boats

- Textile Moisture Meters

- Biomass Moisture Meters

- Other Moisture Meters

- Pit Gauges

- Stroboscopes and Tachometers

- Surface Profile

- Temperature-Humidity Measurement

- Tension Meters

- Textile Test Instruments

- Ultrasonic Testing Equipment

- Coating Inspection

-

Shop by Brand

- Checkline

- DeFelsko

-

Coating Inspection

- Coating Thickness Gauges

- DeFelsko PosiTest AT Adhesion Testers

- Oven Temperature Data Loggers

- DeFelsko PosiTector SST

- Coatings, Miscellaneous

- DeFelsko PosiTector 6000

- DeFelsko PosiTector 200

- DeFelsko PosiTector Inspection Kits

- DeFelsko PosiTest PC

- DeFelsko PosiTest Pull-off Gages

- DeFelsko PosiTest DFT

- Holiday Detectors

- Ultrasonic Testing Equipment

- Industrial Maintenance

- Temperature-Humidity Measurement

- Hardness Testers and Durometers

- Moisture Meters

- Surface Profile

-

Coating Inspection

- PCWI

- Imada

- Tramex

- Western Instruments

- Mark-10

- ElektroPhysik

- Micro-Metrics

- Dakota Ultrasonics

- Shimpo

- Paint Test Equipment

- Tensitron

- Optex

- Dillon

- Rex

- AWS

- Mountz

- Hoto

- Honigmann

- Time

- Compact

- Humimeter

- Testex

- Zitec

- Asker

- Alluris

- Horiba

- Industrial Maintenance

- Temperature-Humidity Measurement

-

Horiba Water Quality Meters

- Horiba LAQUAtwin Compact Meters

- Horiba LAQUA Benchtop Meters

- Horiba LAQUAact Portable Meters

- Horiba LAQUA pH Electrodes

- Horiba LAQUA Ion Electrodes

- Horiba LAQUA DO Electrodes

- Horiba LAQUA Conductivity Cells

- Horiba Oil Content Monitor - Analyzer

- Horiba Environmental Radiation Monitor Radi

- Horiba Multiparameter Water Quality Meter

- G.A.L. Gage Co.

- Straightpoint

- Schaller

- Hildebrand

- InnovaTest

- HTM

- Deumo

- AW-Lake

- Digitens

- Delmhorst

- Seekonk

- Microtronics SRL

- Hans-Schmidt

- Wagner Meters

- Mitutoyo

- Erichsen

- Aqua-Boy

- Gedore

- Bareiss

- NDT

- Checkline

Dakota Ultrasonics CMX1-DL (CMXDL) Data-Logging Ultrasonic Coating Thickness Z-171-0003 / Z-171-0005

See More Ultrasonic Thickness GaugesDakota Ultrasonics CMX1-DL (CMXDL) Data-Logging Ultrasonic Coating Thickness Z-171-0003 / Z-171-0005

Price:

$2,575.00

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

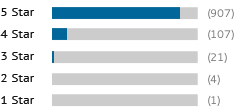

4.8

Out of 5.0

Overall Rating

98%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

April 23, 2025 by Larry B. (United States)

“fast easy and clean interface loved it”

Verified Buyer

April 22, 2025 by Julio M. (United States)

“La pagina es bien sencilla de navegar”

Verified Buyer

April 1, 2025 by Alan L. (United States)

“Quick and Easy”

Contact US

ABQ Industrial

21 Waterway Avenue

Suite 300

The Woodlands, TX 77380

U.S.A.

21 Waterway Avenue

Suite 300

The Woodlands, TX 77380

U.S.A.

Tel: 1-888-275-5772

Tel: 1-281-516-9292

Fax: 1-866-234-0451

E-Mail: info@abqindustrial.net

Tel: 1-281-516-9292

Fax: 1-866-234-0451

E-Mail: info@abqindustrial.net

We Accept

Copyright © 2025 Abq Industrial